Forward Clutch

Forward Clutch

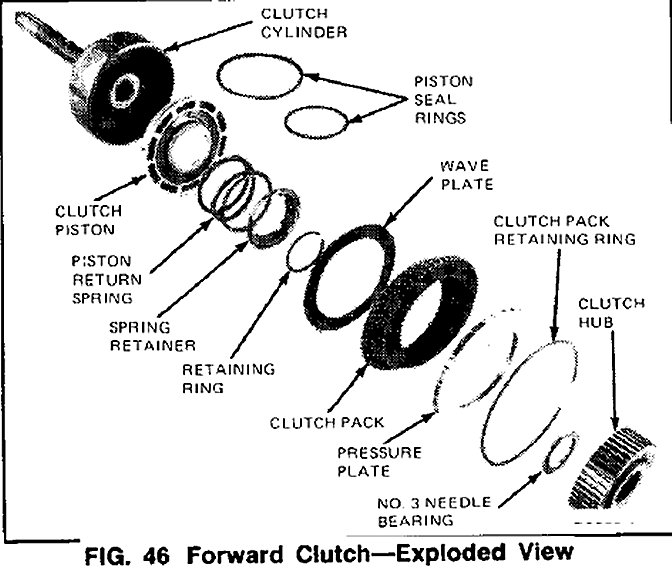

Refer to Fig. 46.

Disassembly

1. Remove the clutch hub and No.3 needle bearing, if not already removed.

2. Remove the clutch pack selective retaining ring.

NOTE: To aid handling, the clutch may set in the extension housing or a "2" diameter hole may be cut in the work bench.

3. Remove the clutch pack.

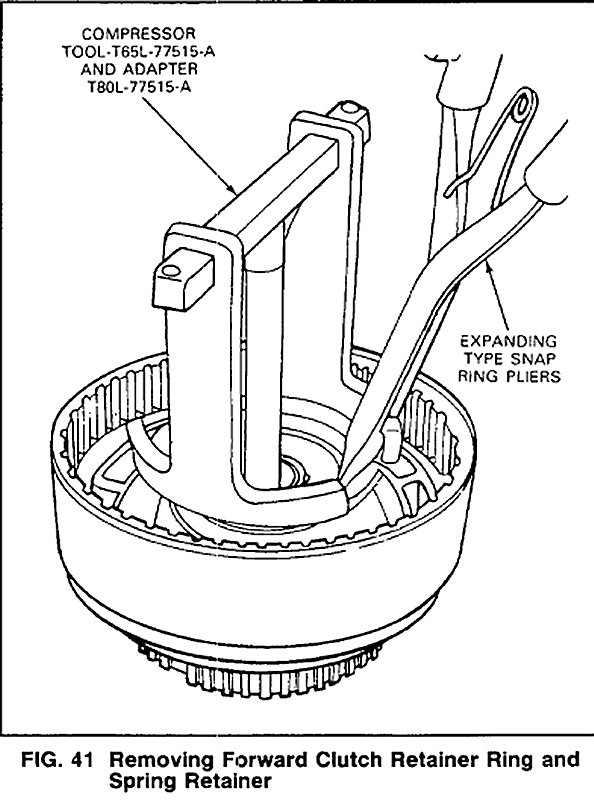

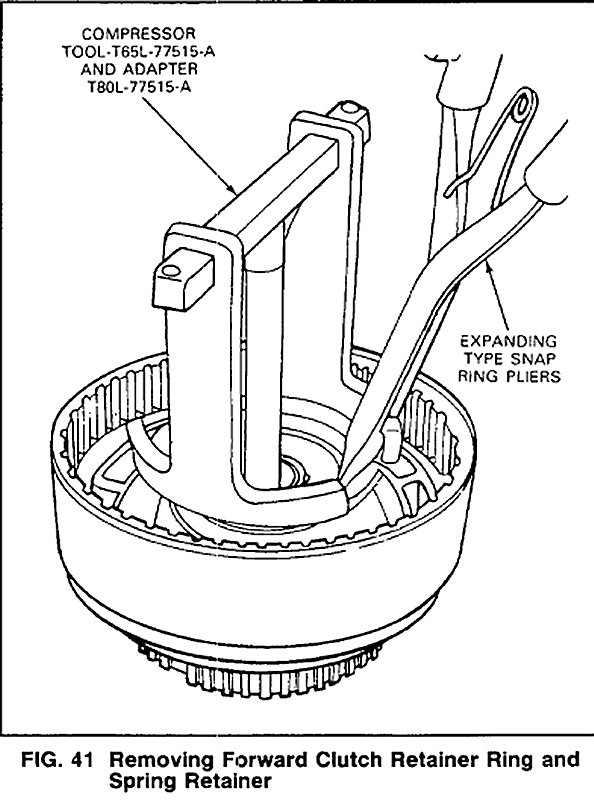

4. Compress the piston return spring using Tool T65L-77515-A and forward clutch adapter Tool T8OL-77515-A (or equivalent) (Fig. 41). Remove the retaining ring and spring retainer.

5. Remove the clutch piston.

6. Make sure that the two ball checks in forward clutch cylinder are tree.

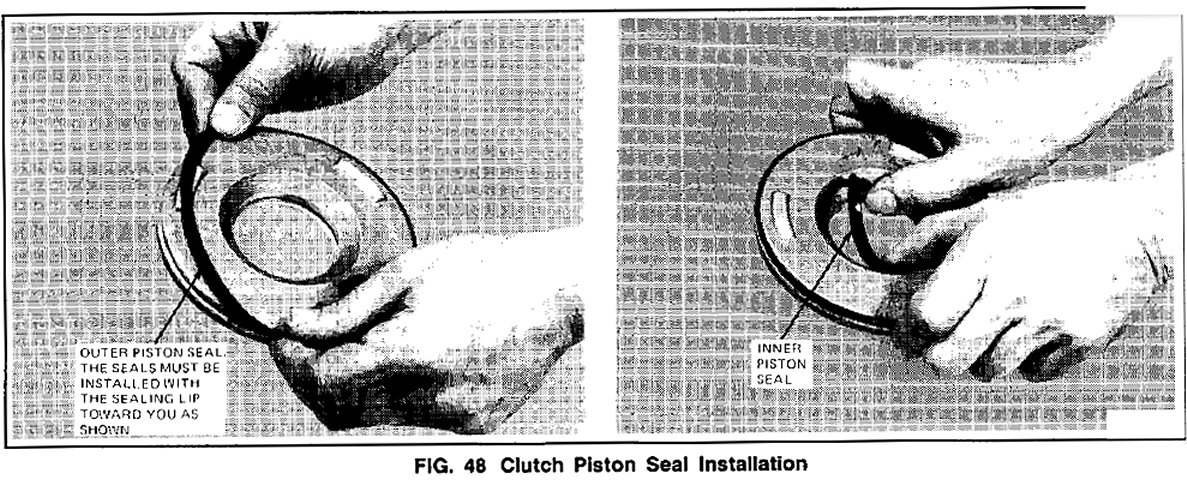

7. Note the position of the inner and outer piston seals, then remove them.

Assembly

1. Install new seals on the clutch piston. Note the direction of the sealing lip before installation (Fig. 48).

2. Install the clutch piston as follows:

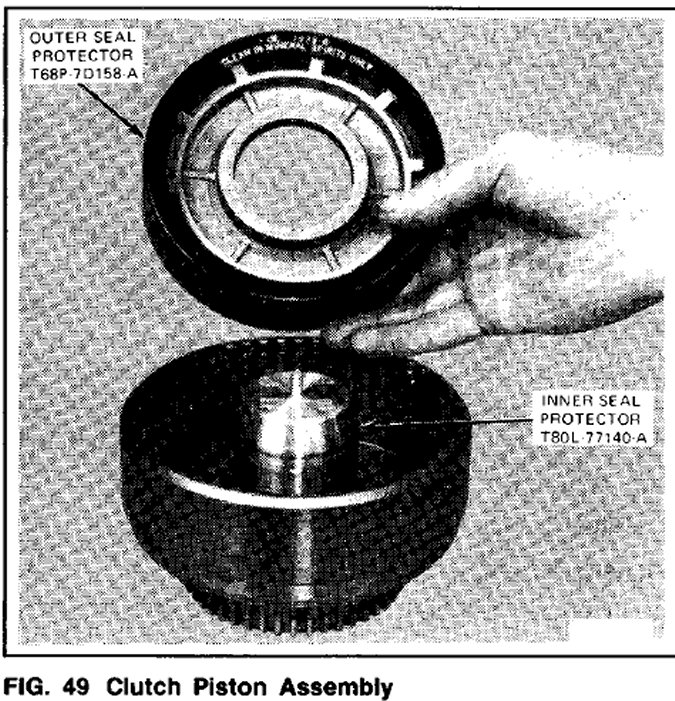

a. Coat the piston seals and the clutch drum sealing area with petroleum jelly.

b. Install the inner seal protector, Tool T8OL-77140-A or equivalent, over the clutch cylinder hub (Fig. 49).

c. Install the piston in the outer seal protector, Tool T68F-7D158-A or equivalent (Fig. 49).

d. Position the seal protector and piston in the clutch drum Push the piston to the bottom of the drum using even thumb pressure

3. Install the piston return spring, the spring retainer and the retaining ring. Compress the piston return spring using compressor Tool T65L-77515-A and forward clutch adapter Tool T8OL-77515-A (or equivalent) as shown in Fig. 41.

4. Install the clutch pack. The wave plate must installed first.

5. Install the clutch pack retaining ring and check the clearance between the ring and the pressure plate. The pressure plate should be held downward as the clearance is checked.

The clearance should be:

4.9L (300 CID) 1.02-1.80 mm (0.040-0.071 in.)

5.OL EFI (302 CID) 1.27mm-2.26mm (0.050-0.089 inch)

If the clearance is not within specifications, selective snap rings are available in the following thicknesses:

0.060 to 0.064

0.074 to 0.078

0.088 to 0.092

0.102 to 0.106 inch.

Install the correct size snap ring and recheck the clearance.

6. Check the clutch for proper operation using air pressure. The clutch should be heard and felt to apply smoothly and without leakage.